In the ever-evolving landscape of power generation, Wolverine Power Cooperative stands out for its innovation in generation and transmission to provide reliable and affordable electricity to our members. The Hersey power plant’s chiller system is another example of our commitment to embracing industry technologies to better serve our members.

The Cold, Hard Facts

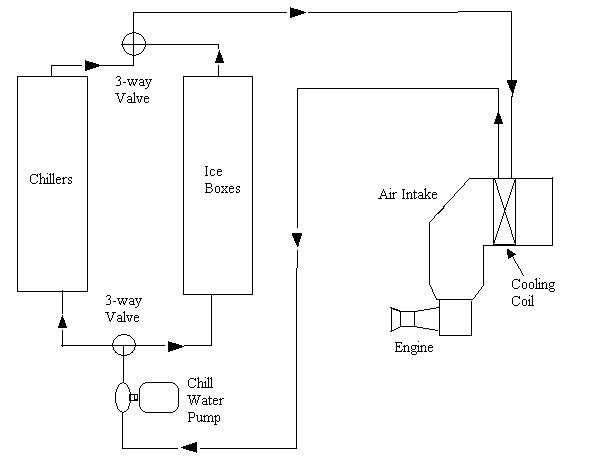

As Hersey Chief Plant Operator Steve Turmo explains, the chiller system gives Wolverine the ability to increase generator output power by using cold water to chill intake air. The chiller units cool water before it goes into the air intake cooling coils and back to the chiller units (cooler the air, the more horsepower, the more MWs we can make). We run chillers when demand is high, and prices are low.

Additionally, the units have the option to build and burn ice. The process is similar, but once the water is cooled, it goes through ice boxes to make ice. We burn ice when demand is high, and prices are high. By building ice at the end of the night when prices are cheaper, we can burn that ice during peak hours and have a surplus to sell on the market. The choice between running the chiller or burning (consuming) ice allows Wolverine to dynamically adjust power output based on demand. By raising the set point slightly, the chiller system contributes an additional 3 MW per generator during peak demand, making it an asset in Wolverine’s power generation arsenal.

The chiller system, at Hersey power plant, offers a reliable and low-maintenance tactic to generation. The traditional method of power augmentation in gas turbines is peak fire mode which increases the temperature inside the unit. This method is effective, but the increased temperatures cause the internal components to wear out quickly. Unlike peak fire mode, the chiller system causes no additional wear and tear.

“If maintained correctly,” said Turmo. “It could run forever.”

Turning Megawatts into Moolah

During peak hours in the summer, Wolverine’s generation team and merchant operations team coordinate to best utilize the added capability and maximize revenue. During periods of high demand, the chiller water pumps cold water into a radiator, cooling the air and increasing its density for enhanced power output. In hot weather conditions, burning ice has also proven to be a financially rewarding strategy, with each cycle lasting approximately four hours. The increased output performs like a battery, storing the energy by building ice overnight and injecting energy via higher output in the afternoon or evening. The ability to quickly ramp up output helps offset volatility from intermittent renewables and capitalizes on market opportunities.

“If prices were to go to the maximum of $3,500/MWh,” said Manager of Power Supply Lucas Johnson, “A 1MW difference can result in an extra $3,500 in revenue per hour.”

While Johnson notes that it’s more common to see prices in the few-hundred-dollar range during high demand, hot summer days, the impact is still impressive. Offering higher capability to the market on a daily basis also demonstrates to MISO that we have the ability to respond when needed. With capacity auction prices low this year, the value fell into the thousands of dollars range.

“However, as capacity becomes scarcer and prices rise, 1MW of capacity could be worth $80,000 or more per year,” said Johnson.

Wolverine’s willingness to adopt less conventional methods like the chiller or ice system reflects the company’s creativity and dedication to exploring alternative avenues in power generation. As the energy landscape continues to transform, Wolverine’s generation assets stand ready to complement intermittent resources and balance the increasingly complex demands of the grid.